Details

Automatic Turntable Sandblasting Machine

This is a smart sandblasting machine developed by our company with many years' experience of customers' practice. It realize both manual and automatic blasting, applying to different shape of parts which requires higher finishing quality based on efficiency.

This sandblasting cabinet designed with an turntable achieves high processing efficiency. As a group of auto guns blasting and swinging the turntable rotates automatically at the same time, thus all surfaces and corners of the object can be cleaned. The turntable can be designed to suit different workparts, such as heavy turntable for wheels, small turntable for bottles, etc

Automatic Turntable Sandblasting Machine Features

1. The blasting machine can be set both manual and automatic work to meet your different demands

2. The quantity of blasting gun can be customized as actual requirement

3. Blasting time can be set on the front intelligent panel, when time arrive, the blast gun stop automatically.

4. Suitable for complex and irregular shaped workparts, obtain excellent finishing results, ensure quality consistency for batches.

Automatic Turntable Sandblasting Cabinet Details

Intelligent Control Panel to Set Blasting Gun, Blasting Time, etc

Intelligent Control Panel to Set Blasting Gun, Blasting Time, etc Regulation Valves and Guages

Regulation Valves and Guages Blasting Gun Group: each gun can be controlled individually

Blasting Gun Group: each gun can be controlled individually

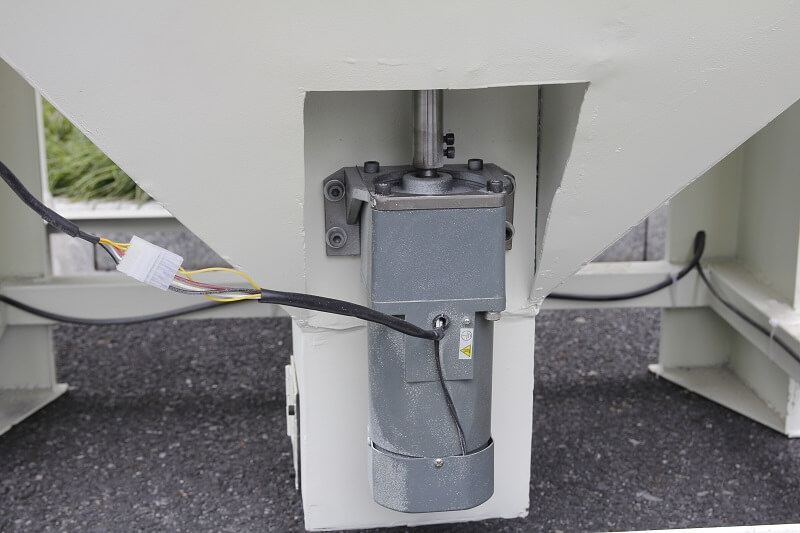

Motor for Turntable

Motor for Turntable Fan Motor for Cartridge Filter Dust Collector

Fan Motor for Cartridge Filter Dust Collector Foot Pedal Switch: facilitate operation when manual work is needed.

Foot Pedal Switch: facilitate operation when manual work is needed.

COLO-1010Bs-3A Automatic Sandblasting Cabinet Specifications

| Model | COLO-1010BS-3A |

| Working Chamber Size | Length1000 x Wdith1000 x Height800 (mm) |

| Dust Collector Type | Cartridge Filter |

| Dust Collector Fan Motor | 0.75kw |

| Voltage | 110V/220V (custom as local) |

| Frequency | 50-60HZ |

| Lighting | 18w fluorescent |

| Blasting Gun | 3 piece, with boron carbide nozzle |

| Compressed Air Pressure | 5-7 bar(kg/cm2) |

| Air Flow | 0.8-3m3/min(1 cubic) |

COLO Sandblasting Machine Advantages

1. Standard configuration is a filter cartridge dust collector with fan that effectively removes dust keeping clear working chamber. Could be optionally designed with cyclone separator for special application, such as using ultra fine abrasives.

2. A bottom funnel contains blasting abrasives that can be recycled for many times, a great saving of production expense.

3. Our sandblaster cabinet is welded from 2mm durable steel plate, whose surface is powder coated, sturdy and wear-resistance.

4. Assembled shipment, only requires simple electric and pneumatic connection when you receive the blaster before use.

5. Sizes and special types can be custom designed as we have experienced technical and manufacture team.

View more about Automatic Turntable Sandblasting Machine on main site